|

Plot the critical path (red line |

Flow Charting

| Main Help Page

Flow Charting

|

Flow Charting the Process

The first step in process mapping is to determine the flow or sequence of steps/activities that is required to complete a process task. This information can be gathered by routings or interviews. It may also be beneficial to gather people from different areas of the company to discuss how information or activities flow from one department to the other. Flow charting a process will help in organizing the tagging activity for process mapping. It is critical to acquire information on every process/path that takes place to complete a task. Critical Path The critical path on a process map is simply the longest path that a part has to travel to complete a task. There are four major flow chart scenarios that may be encountered: |

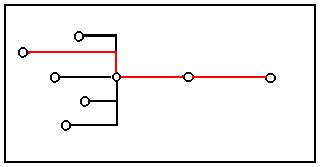

1. Parallel Process Flow Chart

Sub-assemblies or sub components are built simultaneously and brought

together at a common point for final assembly or process.

|

Plot the critical path (red line |

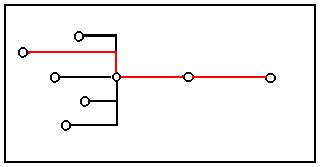

2. Pseudo-Parallel Process Flow Chart

Sub-assemblies or sub components are built as the product is being assembled.

|

Plot the critical path (red line |

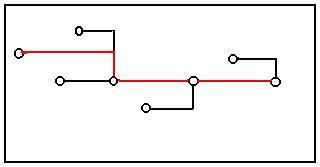

3. Outside Operations Flow Chart

<Back to Top>

Part is shipped out of the department or facility for processing before

continuing to the next step. Example: Outside heat treat, special

machining, plating, etc.

|

Plot the entire path (red line |

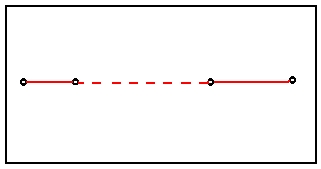

4. Component Assembly Flow Chart

Component parts are assembled together down a central assembly line.

|

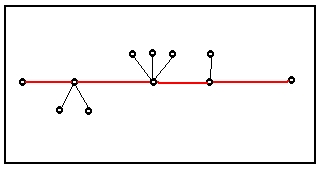

Plot the central critical path (red line |

Process Mapping Home Page | Online Process Mapping | Guide to Online Process Mapping | Process Mapping Methodology

Last Modified on: 5-Apr-2001

Please forward any comments

to

our email

Copyright © Process Mapping

All Rights Reserved

Page Design, Creation & Graphics © 2001-2009 GCA Webpage Publishing

All Rights Reserved. Do not copy or redistribute in any

form.