(Mounting and Clamping)

|

|

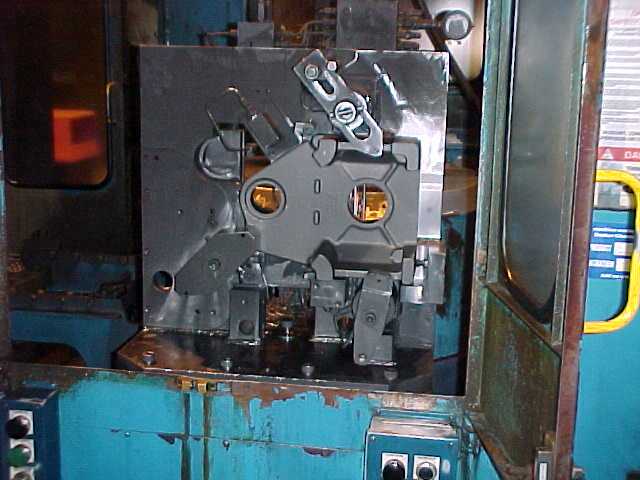

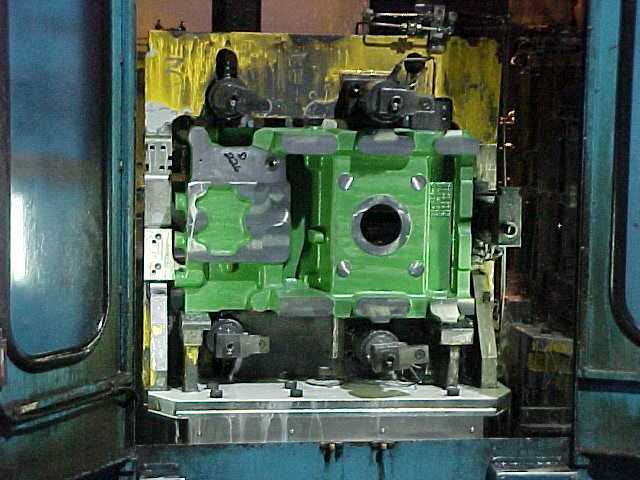

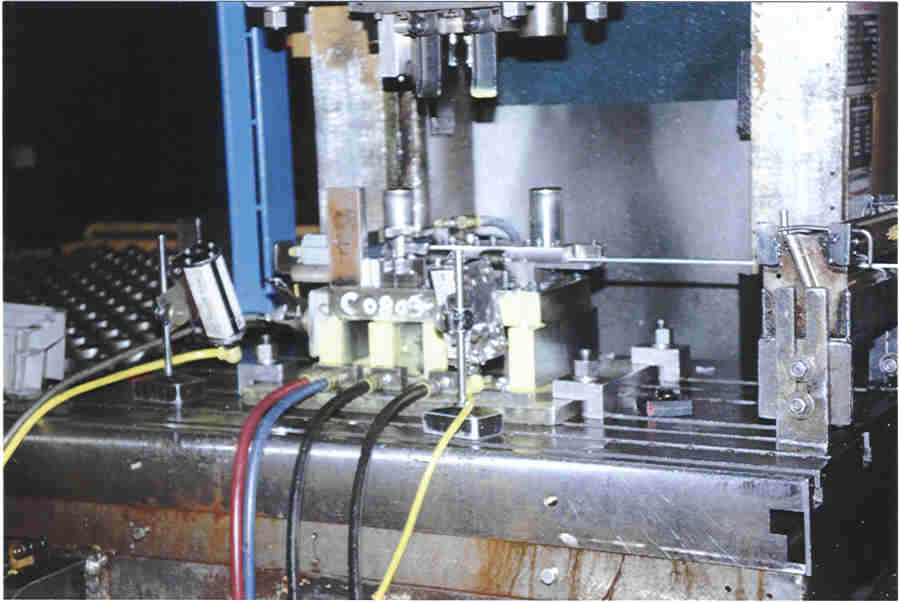

| Hydraulic helps to eliminate clamping adjustments during change-overs. |

| Adjustable clamping introduce flexibility to a fixture making it possible change easily from one part to another that uses the same fixture. |

| Hydraulic ensure clamping consistency and minimizes adjustments. |

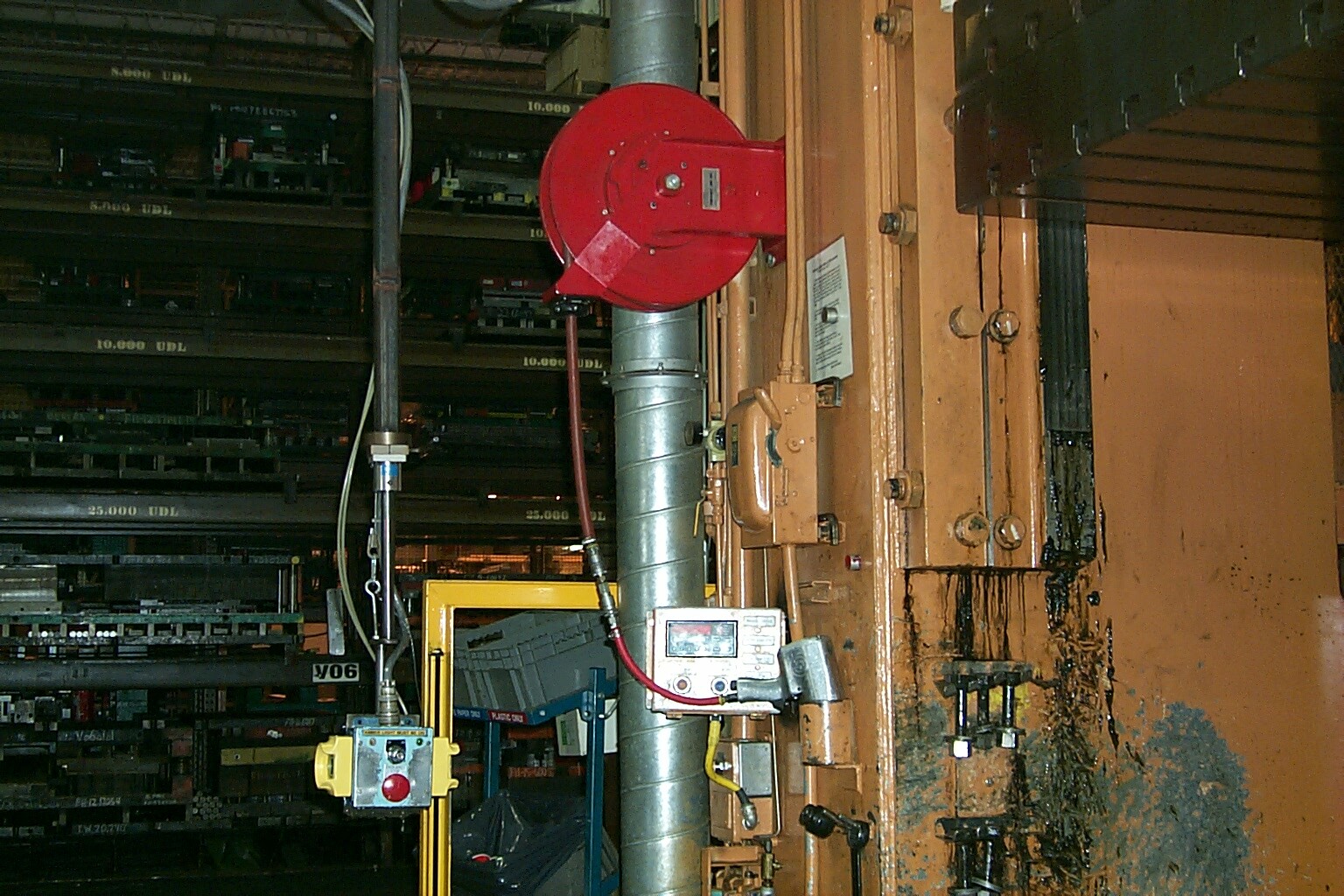

| You can attach a pneumatic impact wrench to a reel and hang it on the machine for easy access. |

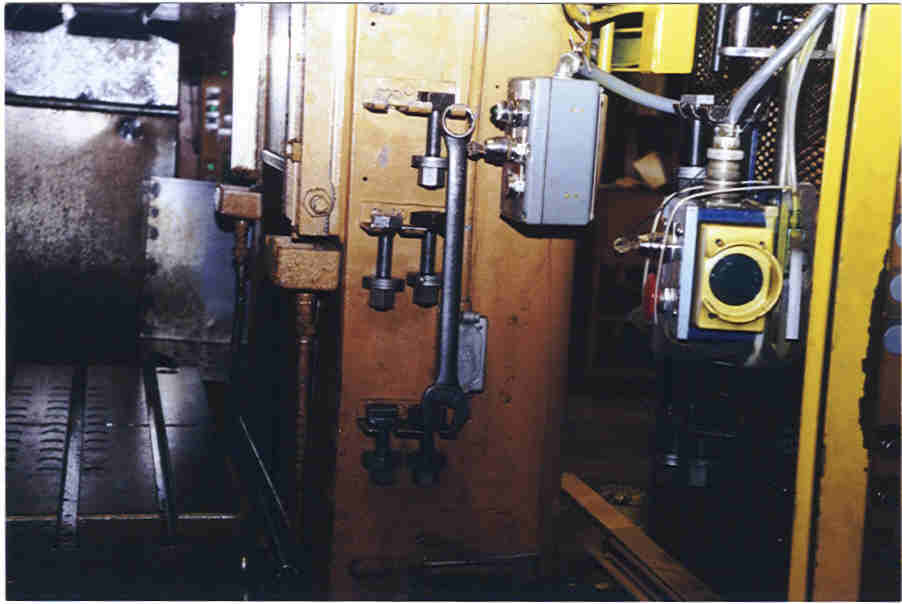

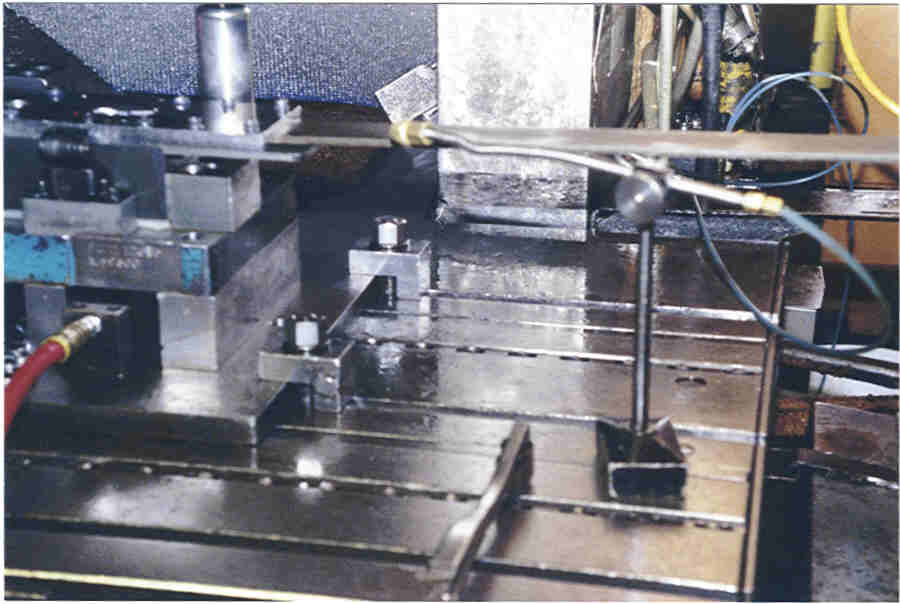

| Standard T-bolts, washers, and nuts are used to rapidly secure die subplates. Notice that the bolts are stored on the press. |

| L-clamps, T-slots, subplates, and standard T-bolts make for a very quick and effective clamping system. |

| Quick connect couplers and color coded hoses will reduce setup time and reduce the possibility for operator error during setup. |

Last Modified on: Monday, 26-Jun-2000 Please forward any comments to our email

Copyright © Process Mapping

All Rights Reserved

Page Design, Creation & Graphics © 2001-2009 GCA Webpage Publishing

All Rights Reserved. Do not copy or redistribute in any form.